Blog: Nuts! By: John Heisz

Having cut the wooden screw thread, I started thinking of possible ways to make the nut that would work with it. One idea was to create a thread cutting tap. This would be a length of the wooden screw that has a steel cutter let in – the steel cutter would cut the threads in a wooden block. Of course, given the size of the screws I want to make with this contraption, this would probably not be an easy task to do. The cutter would have to be razor sharp and certainly wouldn’t stay that way.

There had to be another way. I got to thinking about cutting the threads in the nut with a router and how this could be done. I thought that if the nut were cut into thirds, the threads could be cut with the router mounted in a swing. The arc of the swing would equal the radius of the wooden screw. The blank could be angled off parallel from the swing by the same degree as the lead angle of the wooden screw. At this point I’m feeling pretty good about the idea.

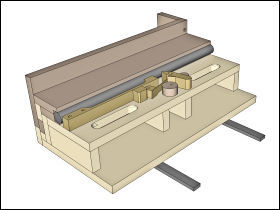

More thought, and I concluded that splitting the nut into quarters would be a better approach. Not only does this make layout of each quarter easier than to do one-third, it also makes it so that only one type of “building block” needs to be made. I’ll explain, but first here’s the rough idea:

.jpg)

Picture a small trim router (like the one used for cutting the wooden screw) mounted in the large hole and that gray shaft as the 1/4″ router bit. It swings back and forth to cut the first groove and then the work is moved to the right 1/2″ and the other groove is cut. The blanks are 1/2″ thick.

From above:

.jpg)

At first I thought that two different types would have to be cut, but realized that if they were positioned correctly, this one type could be stacked to form the entire nut:

.jpg)

Pretty clever, if I do say so.

Should be interesting to see how it works in the real world and I expect I will be trying this out shortly.

As always, stay tuned!