Blog: Woodworking Step By Step By: John Heisz

I occasionally get comments on my videos that go like this:

“I’m a pretty good woodworker, but that (project) is beyond my ability.”

And while I understand where that comes from, mainly because I used to think the same way, that’s the wrong mindset to have. Everything that looks complex is just a series of simple steps. If you’ve developed the ability to work with wood, there’s not much you can’t do with it if you break the process down into steps. It takes some planning and thought to do each step in the correct sequence, but you don’t need to be too granular at the beginning.

Say you want to make a small cabinet:

– The first step should be to figure out the dimensions – width, height, depth.

– Next decide what it’ll be made from – type of wood / plywood.

– Make a list of the major parts: carcass, doors, drawers.

Then you can begin by building the carcass and making the drawers that fit into it and the doors that hang from it. Making the cabinet the correct size is the most important factor, if it has to fit in a specific area. If not, you can be a bit more flexible with the amount of attention you devote to making those parts accurately. If you start out with a plan to make a cabinet that’s exactly 24″ wide, it’s not the end of the world if it ends up being slightly bigger or smaller than that.

Learning to give the correct amount of “weight” to the multitude of factors that affect the final result is important. Obsessing over minute details that won’t even be noticed in the finished project are counterproductive. Likewise, spending excess time on joinery that’s stronger than it needs to be and adds no visual appeal to the project is just as counterproductive. Put you time and effort where it counts.

Treat each part like it’s a project itself. A simple frame and panel door is usually made up of five parts: two rails, two stiles and one panel. That’s at most three small projects that will require your full attention. Each project can be broken down into steps:

– Cut the stock to rough size.

– plane it down to the final thickness and width.

– cut the groove to receive the panel.

And so on.

“That’s easy for you to say, John. You’ve been doing this for decades.”

True, I do have a lot of experience. But all of that brought me here. And I can say with certainty that I wish I’d know this years ago. So look at this as a head start if you are new to woodworking, or a second wind if you are already a good woodworker.

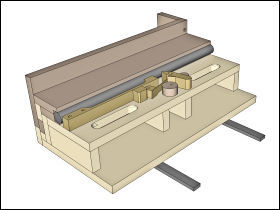

I made a long video of making a small wooden box to illustrate this step-by-step process:

One thing I would change would be to hold off on cutting the front and back panel until after the box was assembled. Then I could directly measure what was needed rather than messing around trying to calculate it and cutting it twice.

Key points from the video:

– make sure your saw is properly aligned with a good quality sharp blade. Don’t just assume, check.

– start with a well defined goal

– a plan with dimensions is best, but it’s not the end of the world if the item is slightly smaller or bigger than intended when finished. Develop the ability to adapt as you go along.

– concentrate on breaking the project down into simple steps and follow those through to completion. Every woodworking project, regardless of how complex, is just a series of simple operations.

– make sample cuts. It’s very important to know exactly what you are getting when you make the cuts on your finished parts.

– pay attention and don’t be lazy. Woodworking isn’t a race to the finish for most people. Take the time to do it right and you’ll enjoy it much more.

– learn to rank the importance of the different factors of the project. For example: The type of wood used will be more important if overall appearance is near the top, but much further down if you are you are going to paint the project as the final finish. Hardwood is stronger than softwood, but not by a huge margin and often you won’t need that extra strength.

– wood isn’t steel or any other metal, so the margin of error while machining it will be much higher. Don’t get hung up on making parts precisely when it’s not needed. For example: The top and bottom panels of the box were supposed to be 1/4″, but can be slightly thicker or thinner because you will cut the rabbet they fit into after you have the panels made. Or you can sand them down flush afterwards.

– learn about wood and the properties that make it different from other material. The top two are the grain structure / strength axis and how it reacts to moisture in the air. You’ll need to work with both of these on every project and make allowances to deal with the effect they have.