Making A K-Body Style Wooden Bar Clamp Clamps & Vises

NOTE: There is an improved long bar clamp with plans available.

It’s the big one! This clamp is easy to make and can be made as long as you need. I made this one from a regular 2×4, 1/2″ plywood and some common hardware.

First, I made the bar. It is 48″ long, 2″ high and I cut the thickness down to 1-7/16″. I drilled 5/8″ holes about 5/16″ deep starting 9″ from the end and spaced 2″ apart:

.jpg)

These holes are for the moving jaw to lock into.

Next, I cut the parts for the fixed jaw. I drilled a 3/8″ hole through the top part and put in a t-nut. To keep the t-nut from working loose, I drove two screws beside it:

.jpg)

The parts get assembled as shown with glue and brad nails.

.jpg)

The end of the lead screw that goes into the clamp pad was flattened to lock the nut on the end. I find this to be the easiest and most reliable way to keep the nut from coming off:

.jpg)

The nut is threaded out to the end and crushed onto the rod.

.jpg)

The parts for the clamp pad. The top part has a 3/4″ counterbore 1/2″ deep and a 3/8″ through hole. The bottom part is rounded over so that it won’t hang up on the bottom of the bar. The threaded rod is 3/8″ and cut to 9″ long:

.jpg)

The two nuts are jammed together to stop them from coming loose. These parts are left at the original 1-1/2″ thickness to easily move on the thinner bar.

.jpg)

Fully assembled and the handle glued on. I made a flat spot on the lead screw to act as a key to lock the handle on, and used fast setting epoxy to glue it in place:

.jpg)

The moving jaw is next, and that starts with the top block that has been drilled for a 3/8″ x 2″ lag bolt. The head of this bolt locks into the holes in the bar:

.jpg)

The plywood sides are an odd shape to give the jaw maximum support.

.jpg)

I did a stop cut part of the way on the table saw then finished it on the band saw:

.jpg)

The top block needs a slight bevel as shown above, right. This provides more clearance for the jaw to slide on the bar.

.jpg)

Here’s how it looks when the bolt head is out and the jaw can slide:

.jpg)

I make a mark when it’s in this position on the side to get the correct angle for the bottom block.

.jpg)

I then hold the block on that line and draw a new line on the bottom block:

.jpg)

I used my disk sander as an easy way to grind it down to the line. When assembled, the moving jaw should move freely when unlocked.

.jpg)

Last step is to put a cover on the clamp pad. I used 1/2″ plywood for this and used the clamp itself to hold it on while the glue dried:

.jpg)

The bolt head will press into the wood with heavy clamping pressure. I don’t expect there to be a problem with this going much further. Wood will compress, but there is a limit under normal conditions.

.jpg)

The finished clamp. I gave the jaws a coat of paint and sprayed clear finish on the bar to help keep glue from sticking:

.jpg)

What is the saying? You can never have too many clamps?

I already have two of my new wooden k-body type clamps – the first one was the prototype and the second was built for the website article and video, but figured now was as good a time as any to make a few more.

I settled on six, and the first task was to cut the bars:

.jpg)

I had a few comments on the video regarding how straight 2×4 is and you can see from the shavings on the floor, I had to do a little work to take the twist out and make the bars flat and true. These bars were cut from 2×8, which is always a better choice when buying this kind of wood, especially if you let it dry out for a few months.

I’m not going to cover all of the details here, but point out the ways I do things. In the video, I cut some parts on the table saw for “effect” – it looked cooler, but it’s always a good idea to make the cuts in the safest and most practical way. Here I’ve set up a stop to cut these parts to length on the miter saw:

.jpg)

Since it would be very difficult to hold the very short piece pictured below, I don’t use a stop, but make a mark (yellow arrow) on the saw bed itself to line up with the end. Leaving a small piece like this unsecured between the blade and a stop could cause it to get wedged and thrown.

.jpg)

The plywood for the first two was scrap 1/2″ spruce sheathing, but any strong plywood will work well. No mdf or particle board!:

.jpg)

Due to my really good camera work in the video (pat on the back, John!), a few people pointed out that the block split while driving in the lag screw. This was due to the thickened shank going into the 5/16″ hole and had no real effect of the strength of the part. To avoid this, drilling in the length of the shank with a 3/8″ bolt is recommended.

.jpg)

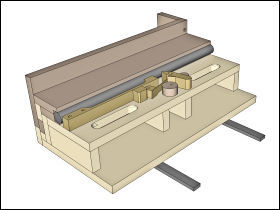

The parts for all six laid out:

.jpg)

In general, I use 5/16″ washers for 3/8″ bolts and threaded rods, since they are a much closer fit. Same for 1/2″, I use 7/16″ washers.

.jpg)

When assembling the fixed jaw, there needs to be a slight gap between the clamp pad and the bar, so that it will move freely and not drag. Usually, when drilling the hole in the clamp pad, it will be slightly off centre and this can be taken advantage of here by rotating the pad to have the make the gap:

.jpg)

When gluing the handle on with epoxy, the flat spot should face down so that the epoxy will pool into the flat spot. If it’s facing up, it may not fill and be less effective at keying the handle on the rod.

.jpg)

In the video I used urethane in a spray can to coat the bar, but a better way is to brush it on. This coating will make it easy to clean off glue squeeze out:

.jpg)

I also gave the handles a single coat of brushed on urethane to help keep them clean.

.jpg)

I let the first coat of urethane dry overnight, then gave it a light sanding and a second coat:

.jpg)

The Rack

With eight long bar clamps taking up space on my workbench, I got to work on a simple rack to hang the up on, out of the way. The perfect spot is between the tool board and router bit cabinet:

.jpg)

I laid out the clamps to determine the spacing and made some measurements. They need to be well supported, and easy to remove and put back.

.jpg)

Pretty basic, just two pieces of spruce 2-1/4″ wide, 1-1/2″ thick and 24-1/5″ long, plus some pieces of 1/4″ plywood:

.jpg)

The plywood tabs stick up 1/2″ to hold the clamps in place. The bottom bar just holds the clamps off the wall.

.jpg)

To mount the bars, I’m using drywall anchors:

.jpg)

I also ran a bead of glue on the bars before screwing them to the wall. As the clamps are fairly light and the rack shouldn’t suffer any impact loads, the wall anchors and glue will be quite strong enough.

.jpg)

Finished:

.jpg)

Neatly hung up and in a very convenient place.

.jpg)

I made a short video of the clamp rack build and installation:

Here’s a short video showing the build from beginning to end:

An easy to make, economical and very effective clamp – well worth the time to build a few. I’ll be make five more soon, to go with this one.